RF Manufacturing Capabilities

Epec Engineered Technologies is global manufacturing company that provides cost-effective products with the world class quality. Our facilities occupy over 100,000 square feet and are ISO9001: 2015 certified.

We conduct all of our radio frequency product design, assembly, and test activity within a 52,000-square-foot, state-of-the-art facility in New Bedford, MA that is equipped with the latest in design software, test instrumentation, prototype and manufacturing equipment.

Investment In Equipment

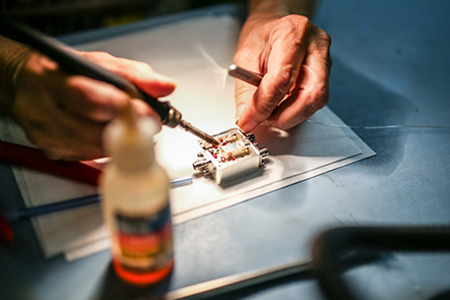

Our lean manufacturing and assembly lines which allows Epec to have wide variety of products in production at the same time. From special vision systems to automated test equipment, solder reflow and crystal tuning along with our own machine shop, this investment allows Epec to reduce cycle time and help our customers get to market faster.

Along with our substantial investment in equipment, production technicians follow all requirements in the corresponding work instructions including quality control procedures necessary to assure the product exceeds the stated requirements and guideline including IPC standards. Our paperless system assures that we are always using the most up to date documents and provides electronic tracking of operator processes.

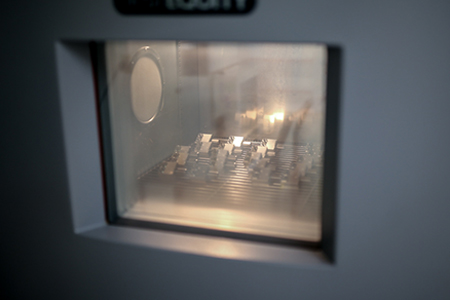

Our clean rooms and a complete range of in-house RF and environmental testing capabilities support our high-reliability space and military projects.

The table below is a partial listing of Epec's testing capabilities.

| Test | Test Method Standard |

|---|---|

| Visual | Mil-STD-883, Method 2017 or IPC-610A |

| Thermal Shock | MIL-STD-202, Method 107 or MIL-STD-883, Method 1011 |

| Electrical | MIL-F-18327E or ATP |

| Vibration | MIL-STD-202, Method 214 |

| Mechanical Shock | MIL-STD-202, Method 213 |

| Humidity | MIL-STD-202, Method 103 |

| Moisture Resistance | MIL-STD-202, Method 106 |

| Life | MIL-STD-202, Method 108 |

| Salt Spray | MIL-STD-202, Method 101 |

World Class Manufacturing

This manufacturing facility includes network analyzers, soldering ovens/stations, a state-of-the-art CAD-CAM system, automated optical inspection equipment, and an ISO9000 based quality assurance program to create passive filters, components and sub systems.

Our investment in IPC/JSTD certified technicians and inspector along with our 70 year history of manufacturing high reliability printed circuit boards, ensures that the quality of the product is second to none.