Challenges Designing and Manufacturing Lithium-Ion Battery Packs

Why spend the time and money to develop and manufacture a custom lithium-ion battery pack when off-the-shelf battery packs are radially available? Custom battery packs can be designed to fit the unique needs of an end product’s size and shape, temperature, power, voltage, runtime, and interface requirements, which generic battery packs cannot meet.

Supply chain issues can be avoided with better control of all the components and “end-of-life” surprises prevented. Custom battery packs come with a host of design and manufacturing challenges. Each battery is unique and must be designed and fully tested for the intended application.

In addition, regulatory testing is mandatory to ensure that the new design can safely withstand environmental abuses expected and unexpected in the field.

In this webinar, we review off-the-shelf battery packs compared to custom battery packs, design challenges, requirements, manufacturing, and more.

Watch the Recording Below

View the Presentation Slides

View the Slide Deck on SlideShareCheck Out the Full Q&A

We have compiled all the questions submitted at the conclusion of this webinar into a readable format available on our blog.

Webinar Agenda:

- When should an off-the-shelf battery pack be used and when is a custom battery pack a better choice?

- Defining a custom battery’s requirements to minimize development costs and time to market

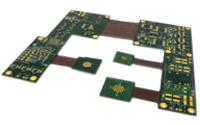

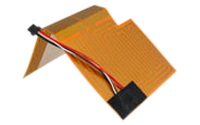

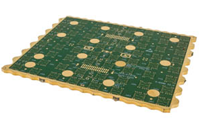

-

How and where custom batteries are manufactured

- What capital expense is required

- Supply chain issues that can factor into you decision

-

Time needed to develop and get a custom battery pack on the market

- What are the driving timeline components?