Managing The Development Of Your Overmolded Cable

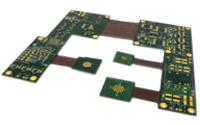

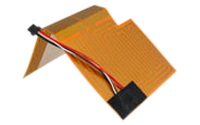

When designing a custom overmolded cable, there are several critical design details that engineers must consider such as the overmold material, physical shape, and the type of bulk cable to be used.

Design changes during development can create significant delays and cause a direct impact on program schedules, especially if hard tooling or custom bulk wire is involved.

Understanding how the cables are produced and the available options to implement design updates can be the difference between completing your project on schedule or a cancelled program.

In this webinar we review overmolded cable assembly material options, manufacturing processes, customization options, and more.

Watch the Recording Below

View the Presentation Slides

View the Slide Deck on SlideShareCheck Out the Full Q&A

We have compiled all the questions submitted at the conclusion of this webinar into a readable format available on our blog.

Webinar Agenda:

- Summary of overmold material options.

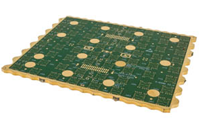

- Typical manufacturing processes and tolerances.

- Customization options.

- Incorporating the bulk cable.

-

Changes to your overmold design – manage the impact.

- Material change

- Durometer change

- Changing the overmold diameter

- Changing the cable jacket diameter

- What information does a custom cable manufacturer need to quote?