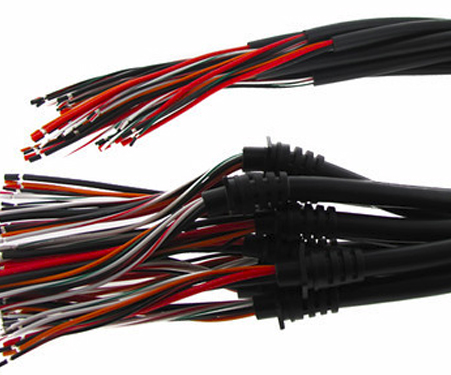

Custom Overmolded Cable Assemblies

Overmolded cable assemblies are wire harnesses that have been encapsulated with molten thermoplastic to protect critical interfaces, improve strain relief, and create a sealed, robust connection point. This process not only strengthens the cable mechanically, but it also helps shield it from moisture, chemicals, vibration, and continual flexing. Due to their reliability and versatility, overmolded cables have become the preferred solution across various markets, including medical devices, industrial controls, robotics, defense equipment, consumer electronics, automotive systems, and many others.

Epec’s overmolded cable capabilities support the full range of applications, from simple low-voltage USB cables to multi-breakout industrial harnesses and large medical harnesses exceeding 100 feet in length. We are a world-class manufacturer of custom cable assemblies, producing millions of cables every year and supporting programs of all sizes.

Overmolded Cable Examples Include:

- Single and Dual-Row Connectors

- Rigid PCBs

- Multilayer PCBAs

- Flex Circuits

- Breakouts and Taps

- Custom Strain Reliefs

- Grommets

- Splitters

- LEDs

- Switches

- Discrete Components and Sensors

Domestic and Offshore Overmolded Cable Capabilities

To meet the sourcing and speed needs of modern supply chains, Epec offers both domestic and offshore overmolded cable assemblies. Each location has its own advantages.

Our offshore operations support ultra-low-cost production and medium to high-volume programs, while our domestic facility in New Bedford, Mass., is ideal for fast-turn, strategic, or classified projects that benefit from stateside manufacturing, local engineering access, and tariff-free sourcing.

With this combination of global capacity and domestic responsiveness, we provide customers with dependable, scalable, and fully customized overmolded cable solutions.

Domestic American-Made Overmolded Cables

Epec’s domestic overmolding facility is located in New Bedford, Mass., and is equipped with injection molding capacity up to 7 kW. This location focuses on thermoplastic injection molded overmolds, offering precise molding control, tight quality oversight, and short lead times.

With stateside warehousing of raw materials and finished goods, our domestic manufacturing is ideal for low- to medium-volume programs, rapid development efforts, and strategic sourcing requirements. All cables are produced without international transit risk, customs delays, or tariff impacts.

Why Choose Epec’s U.S. Overmolded Cable Manufacturing?

- Made in the USA: Our U.S. facility meets the highest quality standards while supporting domestic sourcing and Buy American preferences.

- Faster Turnarounds: Eliminate long transit times and reduce production risk with local manufacturing.

- Tariff-Free: Avoid the unpredictability and added cost of international tariffs.

- Full Engineering Support: Work directly with our U.S.-based engineering team to design and prototype your custom overmolded solution.

- Perfect for Low-to-Mid Volume: Get the precision and responsiveness you need without high minimum order quantities.

Customers Benefit From:

- A highly flexible production cell tailored to prototype through mid-volume work.

- Direct access to U.S.-based engineering and product teams.

- The ability to easily visit our facility and review production in person.

While typically not the lowest cost decision, domestic overmolding is an excellent option for customers who need speed, tight control, and local support throughout the manufacturing process.

Global Operations for Cost-Sensitive Projects

While many customers turn to our U.S. manufacturing for speed and flexibility, others require ultra-competitive pricing for high-volume or cost-sensitive programs. That’s why Epec also operates a global manufacturing network in low-cost regions, giving our customers the ability to balance cost, complexity, and speed depending on their specific project needs. We maintain a large network of vetted production partners across multiple low-cost regions, allowing us to match project requirements with the best manufacturing solution.

Whether you're prioritizing cost-efficiency or domestic production, Epec has the right solution.

Our Global Facilities Support:

- High volume overmolding at competitive pricing.

- Custom extrusions of UL and non-UL wire.

- An extensive library of form, fit, and function equivalent connectors and terminals.

- Dozens of existing house overmold tools available with zero NRE costs.

- Full UL, RoHS, REACH, and ISO compliance.

Epec maintains a strong direct employee presence across our partner facilities. Our teams speak the local languages and are stationed onsite to oversee production, expedite schedules, and perform in-process quality inspections.

Combined with our domestic engineering, customer service, and quality teams, this creates a global sourcing strategy that delivers excellent value, strong communication, and a steady supply chain for customers.

Custom Overmolded Cable Capabilities

Epec’s overmolded cable capabilities cover a wide range of materials, wire types, termination styles, and environmental durability requirements. Every program is built around the specific mechanical, electrical, and environmental conditions of the final product.

We mold with the industry’s most common thermoplastic and thermoset materials, including:

- PVC

- TPE

- TPU

- Santoprene

- Biocompatible PVC

These materials are selected based on flexibility, temperature resistance, environmental exposure, sealing needs, and the cosmetic attributes desired for the finished part.

Most overmolded cables pair these materials with common UL-rated wire types, such as:

- UL1007 and UL1569

- UL2464

- UL2517

- Many other UL-rated constructions

- Any non-UL wire type when required

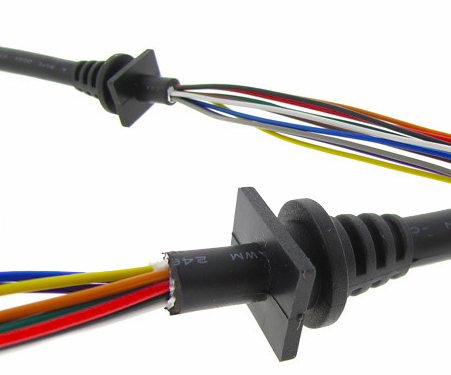

For harsh environments, our team routinely develops assemblies with sealing provisions, gaskets, and overmolds rated up to IP68. This includes fully sealed connectors, overmolds with extended strain reliefs, and dual-stage molding where the first shot encapsulates sensitive components and the second shot forms the outer protective shell.

All wire harnesses undergo strict electrical testing. Continuity is verified multiple times, including in process before overmold is formed and again during final inspection. Leak testing, pressure testing, hi-pot, dimensional checks, pull force testing, and visual inspection are also performed as needed.

Watch Our Video

Custom Overmolded Cable Assemblies Domestic Manufacturing for Rugged Reliability

Design for Manufacturability

A successful overmolded cable depends on early collaboration between design teams and manufacturing engineers. Epec offers complimentary design consultations that focus on manufacturability for all custom overmolded cable projects.

Our engineers will review your concept and identify issues related to mold flow, material compatibility, strain relief geometry, pinout, sealing requirements, minimum bend radius, and connector terminations. This early engagement with our customers helps eliminate risk before tooling is built, saving time and avoiding costly delays.

We can work from any combination of customer-supplied information, including:

- Rough sketches or concept renderings

- Engineering drawings

- STP or 3D models

- Schematics

- Bills of materials

- Statements of work

Typical areas where we assist include:

- Overmold tooling design and feasibility review

- Recommendations for material selection and compatibility

- Waterproofing suggestions for sealed connectors and strain relief features

- Encapsulation techniques for PCBAs, sensors, flex circuits, and sensitive hardware

Additional Resources

Below you will find related resources on our custom overmolded cable assemblies.

- Tips For Developing Custom Overmolded Cable D-Sub Connectors

- Overmolded Cables Using Pins, Receptacles, and Spring-Loaded Contacts

- Flexible Wire Jackets and Overmold Options for Custom Cable Assemblies

- How To Incorporate Magnets into Your Custom Overmolded Cable Design

- Gasket Optimizing for Overmolded Custom Cable Assemblies

- Incorporating PCBs and LEDs into an Outdoor Overmolded Cable Design

- 5 Custom Cable Overmold Designs with No Tooling Expense

- Managing The Development Of Your Overmolded Cable - Q&A

- Applying Artwork In Overmolded Cables

- Overmolded Cable Assemblies: Tactile Design Considerations

- What Is Cable Pre-Molding?

- What Is An Overmolded Cable Assembly?

- How Temperature and Humidity Affect Cable Assembly Overmolding

- Using 3D Prints to Accelerate Overmolded Cable Timelines

Looking For a Custom Overmolded Cable?

Whether you need a simple overmolded connector or a complex multi-breakout harness, we can support your program from concept through production with predictable lead times and strong engineering support.

Discover why Epec's custom overmolded cables are the trusted choice for high-reliability applications across multiple industries. Get insights into our NPI processes, economic pricing, and ready-to-ship inventory.

Request a Quote Request Design Support Request More Information