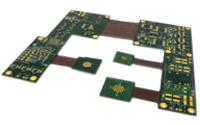

ITAR/Military Flex and Rigid-Flex PCBs

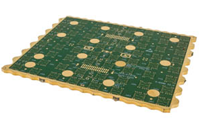

Rigid-flex printed circuit boards help customers reduce their PCB footprint, use fewer parts and interconnections, and tackle more complex design challenges. The next level of flex and rigid-flex PCBs involves designing and manufacturing parts in the U.S. for ITAR, military, and aerospace applications. View full post, ITAR Registered Manufacturer for Military and Aerospace Applications.

These high-complexity, high-reliability applications require extensive engineering and processing knowledge, as well as significant investment in specialized equipment to ensure accurate and consistent production.

The flexible part of a rigid-flex PCB is made from thin, high dielectric constant material like polyimide, with copper traces created through a photo etching process. Experience in this area is crucial to produce highly reliable PCBs and minimize scrap after assembly.

Our NetVia Group facility in Dallas, Texas, has over 25 years of engineering and production experience in flex and rigid-flex PCBs for military, aerospace, and defense applications. With extensive knowledge of both rigid and flexible polyimide PCB materials, along with traditional FR-4 products, we ensure the highest quality regardless of design parameters.

Design Challenges

Epec has over 70 years of design and manufacturing experience with printed circuit boards. We've developed a significant library of challenges commonly faced when helping customers get their parts into production. In the military and aerospace industry, where high reliability, size/weight restrictions, and electrical performance are crucial, we often encounter these challenges in flex/rigid-flex designs:

- High-Density Packages: Components only available in high-density ball-grid array packages requiring via in pad, which do not allow for Class 3 minimum annular ring requirements.

- Mixed Designs: High current and controlled impedance designs requiring thicker copper (1 oz or greater) and dielectrics for impedance lines, negatively impacting flexibility/bend requirements.

- Trace Width and Impedance: Minimum trace width of 0.005" (or greater) design rules combined with controlled impedance requiring thicker dielectrics to achieve impedance values, not meeting bend requirements.

- High Current Requirements: Higher current carrying requirements necessitating copper thicknesses greater than 2 oz, negatively impacting flexibility/bend capability.

- Plated Through Holes: Keeping plated through holes at least 50 mils away from the flex and rigid PCB areas to avoid issues due to the coverlay portion of the flex circuit not continuing through the rigid PCB.

Technical solutions to these challenges can be applied when the entire design and performance specifications are reviewed with our engineering team and the customer design team.

Manufacturing Equipment Investments

To properly manufacture flex and rigid-flex circuit boards for these demanding applications, significant investment in specialized equipment is required to meet the demanding tolerances of high-frequency applications.

Key equipment includes:

- Laser Direct Imaging: Ensures high yield on sub-3 mil lines and spaces with proper adhesion of soldermask dams after developing.

- Plasma Etch: Prepares through holes for plating on the flexible portion of the rigid-flex PCB.

- Laser Drilling/Routing: Drills very small vias, controls depth drill blind and buried vias, and routes out patterns on the coverlay portion of the flex circuit.

- Autoclave Lamination: Provides computer-controlled accuracy and greater heat control for laminating different types of materials (FR-4, Polyimide, PTFE) on RF microwave rigid-flex PCBs.

- X-Ray Drill: Optimizes drill pattern location on laminated boards, especially important when laminating polyimide and FR-4 on rigid-flex PCBs.

- CNC/Optical Machining: Performs precise machining required for high-technology rigid-flex PCB designs, improving lead times and quality control.

Watch Our Video

Lenz DLG-550 in Action: High-Speed, High-Accuracy PCB Drilling

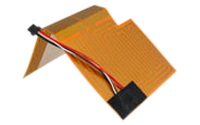

Connector Assembly for Flex and Rigid-Flex PCBs

Epec offers a complete range of miniaturized printed circuit board connectors with high reliability in through-hole and surface mount designs for integration into single-sided, double-sided, and multilayered flex circuitry.

J-STD-001 and IPC Class III Certified

Our facilities, equipment, and technicians are J-STD-001 and IPC Class III certified, ensuring superior assemblies. Our turnkey flex circuit assemblies are designed and produced to exacting specifications, including the use of EMI shielding, polarization, strain-relief/stiffeners, and connector packaging technologies. Our experienced design and manufacturing team ensures that the final design will exceed the mechanical and electronic requirements of the target environment.

Experience the Difference in Quality and Reliability

Make sure your flexible PCBs are manufactured to the highest standards for your military and aerospace applications. Consult our engineering experts today for customized, U.S.-manufactured rigid-flex pcb solutions.

Request a Quote Request Design Support Request More Information